CREATE THE HIGHEST POSSIBLE VALUE

NC LEVELLER FEEDER LINE

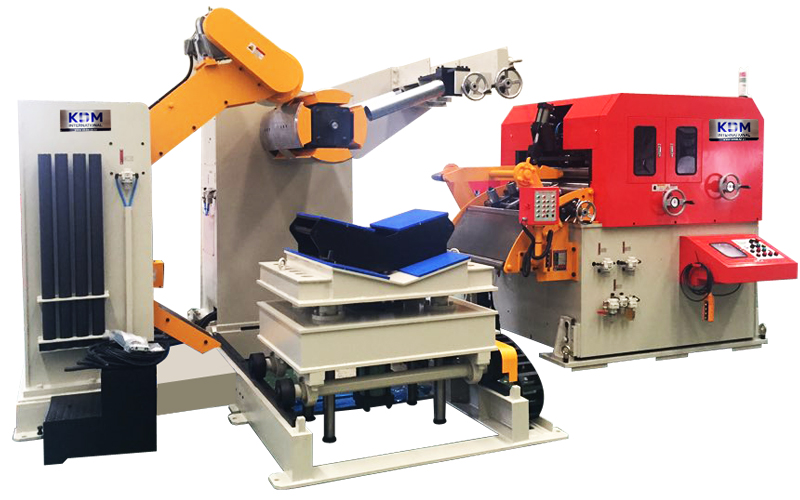

HT-MODEL

▶ Flatness operation can be easily performed when levelling high tension thick plates

▶ Coil injection in the initial stage can be easily performed by applying inserting device and loop table

▶ Rotational speed in uncoiler can be controlled

▶ Electric power is strengthened by applying hydraulic pressure on work rolls and feed rolls

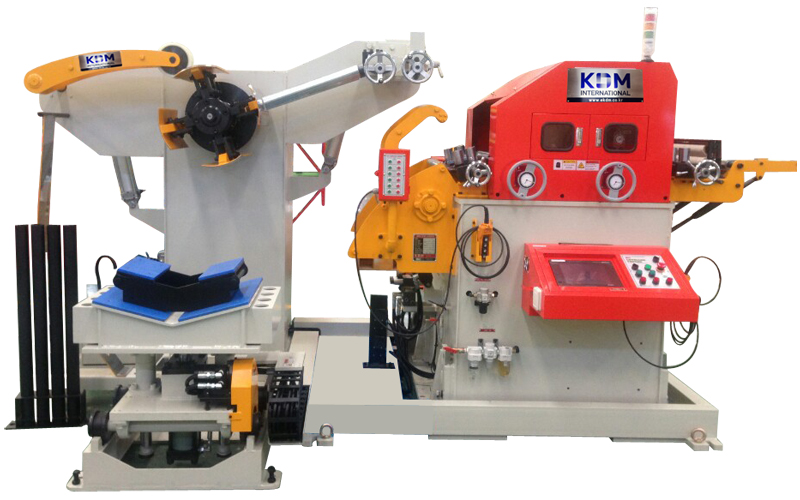

T -MODEL

▶Precise flatness operation can be easily performed when using thick plates

▶ Coil injection in the initial stage can be easily performed by applying inserting device and loop table

▶ Rotational speed in uncoiler can be controlled

▶ It is possible to prevent coil from twisting by applying hydraulic pressure on the opener

ST-MODEL

▶ It is a mixed type of leveller (T-Type) and uncoiler (MT-Type)

▶ Pad band and coil lift are applied to facilitate coil injection in the initial stage

▶ Constant-brake for absorbing inertia in uncoiler and caliper brake are applied

▶ It is possible to prevent coil from twisting by applying uncoiler/opener inverter controls

MG-MODEL

▶ Flatness operation can be easily performed for high tensile steel plates

▶ Electric power is strengthened by applying hydraulic pressure on work rolls and feed rolls

▶ Constant-brake for absorbing inertia in uncoiler and caliper brake are applied

▶ It is possible to prevent coil from twisting by applying uncoiler/opener inverter controls

MT-MODEL

▶ Flatness operation can be easily performed for high tensile steel plates

▶ Electric power is strengthened by applying hydraulic pressure on work rolls and feed rolls

▶ Constant-brake for absorbing inertia in uncoiler and caliper brake are applied

▶ It is possible to prevent coil from twisting by applying uncoiler/opener inverter controls

M - MODEL

▶ M-models can be installed at restricted and small spaces due to its compact design

▶ Safe structure for coil installation and band cutting

▶ Constant-brake for absorbing inertia in uncoiler and caliper brake are applied

▶ It is possible to prevent coil from twisting by applying uncoiler and opener inverter controls

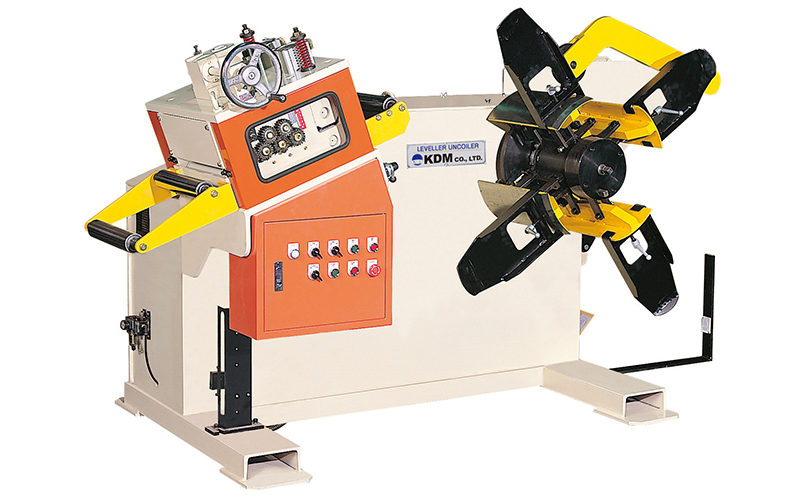

L - MODEL

▶ Outstanding levelling correction of thin sheets used in electronic components, etc

▶ L-models can be installed at restricted spaces smaller than 4 meters

▶ Constant-brake for absorbing inertia in uncoiler is applied

▶ The speed can be changed through uncoiler inverter control

SL-MODEL

▶ Flatness operation for materials smaller than 0.2T~1.6T can be precisely performed

▶ Aluminum and nonferrous materials can be used in SL- models

▶ High speed operation beyond 60 spm is possible

▶ Constant-brake for absorbing inertia in uncoiler is applied

CRADLE

▶ Inserting materials can be performed only by UP-LOOP method

▶ Coil materials can be easily mounted by putting them into the cradle

▶ Inserting device and loop table are applied to facilitate coil injection in the initial stage

▶ It is possible to adjust the cradle according to material widths

ROLL FEEDER

▶ Numerical computer controlled feeder by AC SERVO MOTOR

▶ It is possible to execute precise acceleration/deceleration stops

▶ Execution value, input condition, motion prediction, and feeding speed can be freely set

▶ Easy operation

▶ Releasing type by applying AIR and CAM methods

▶ High speed operation at a maximum speed of 120 SPM

▶ Easy installation

▶ Combination type of leveller and uncoiler

▶ Uncoiler can operate itself when levelling operation is unnecessary

FINE BLANKING/SHEET-LEVELLER

▶ Precise levelling of fine blanks and sheet materials

▶ High quality products and high accuracy are realized by applying work roll cassette type

▶ Optimal roll condition can be maintained by opening and cleaning work rolls

▶ Through memory function, levelling can be easily performed after changing model types

▶ High productivity by applying coil auto loading system